These specialized tools enable high-efficiency machining of intricate profiles, 3D surfaces, and non-standard shapes across critical sectors like aerospace and automotive mold production.

Their characteristics are as follows.

1. High precision and complex shape machining capability

By tailoring the tool profile to the workpiece shape, manufacturers achieve complete machining of complex parts in a single setup, significantly reducing dimensional deviations caused by repeated clamping.

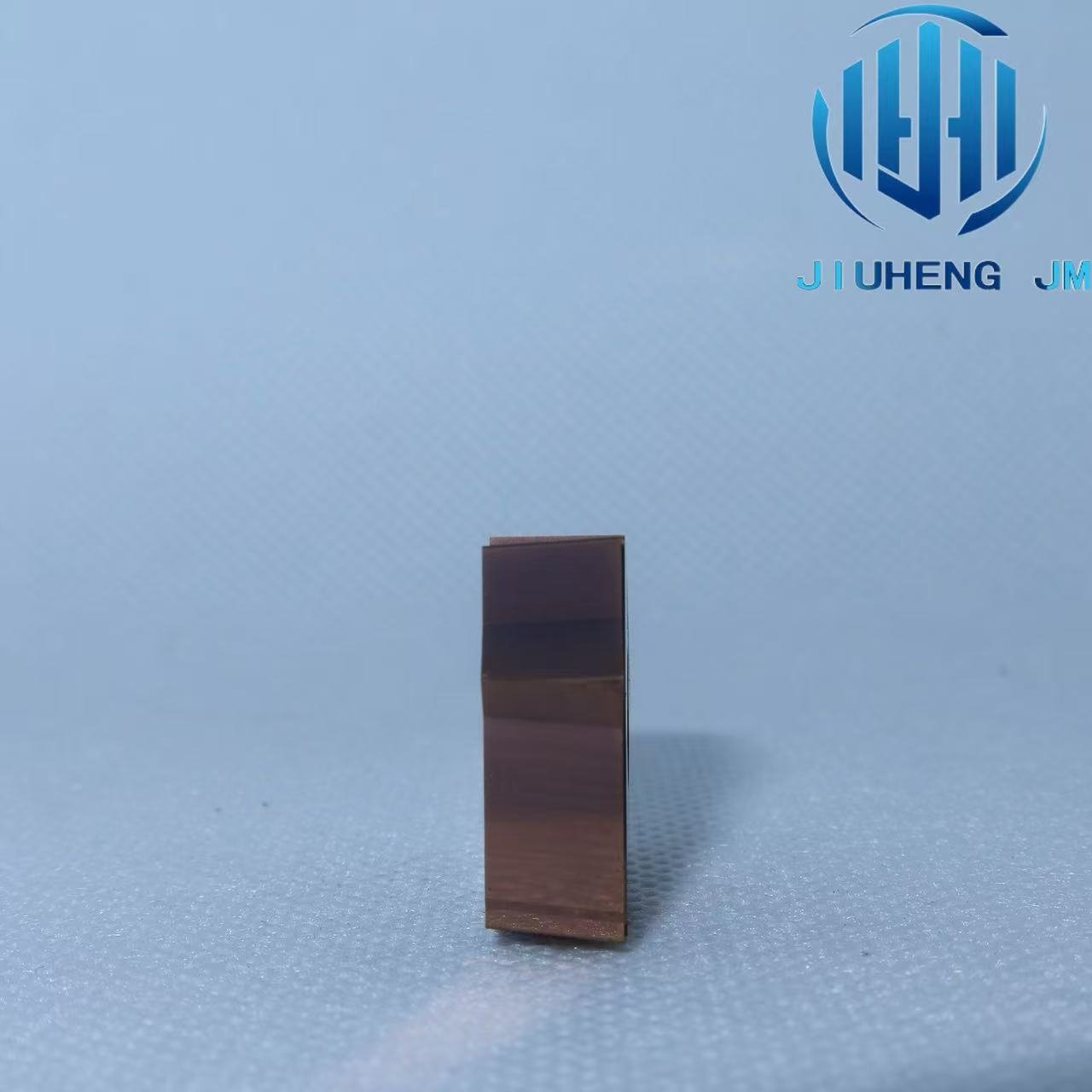

Precision Sharpening: The cutting edge’s shape matches the workpiece’s target contour, ensuring dimensional and surface accuracy (up to the micron level).

2. Specialised design

Non-standard customisation: Mostly customised tools designed for specific workpieces (e.g. involute gear tools, thread milling cutters, etc.).

Composite function: Some tools integrate roughing and finishing functions to improve efficiency.

3. Diverse tool types

Classified by structure:

Integral type: high rigidity, suitable for small batch high-precision machining (such as integral carbide milling cutter).

Welding type: The cutter head is welded to the cutter body, which is economical.

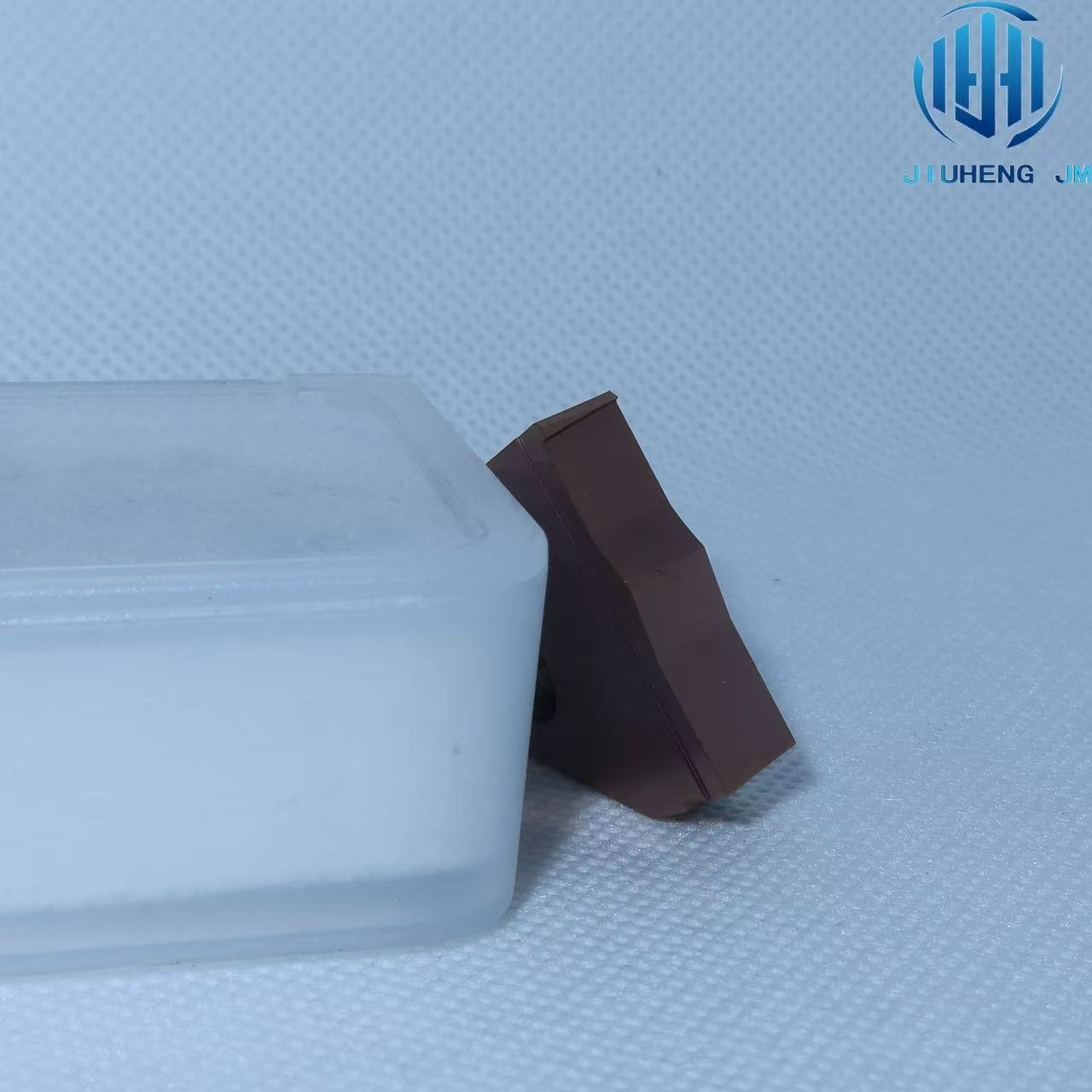

Indexable: the insert can be reused, suitable for mass production.

According to the processing mode:

Contour Turning Cutter: Used for turning complex contours of rotary bodies.

Forming milling cutters for machining 3D surfaces or moulds.

Gear cutters (e.g. hobbing cutters, gear shaping cutters): dedicated to gear shaping.

4. Materials and coating technologies

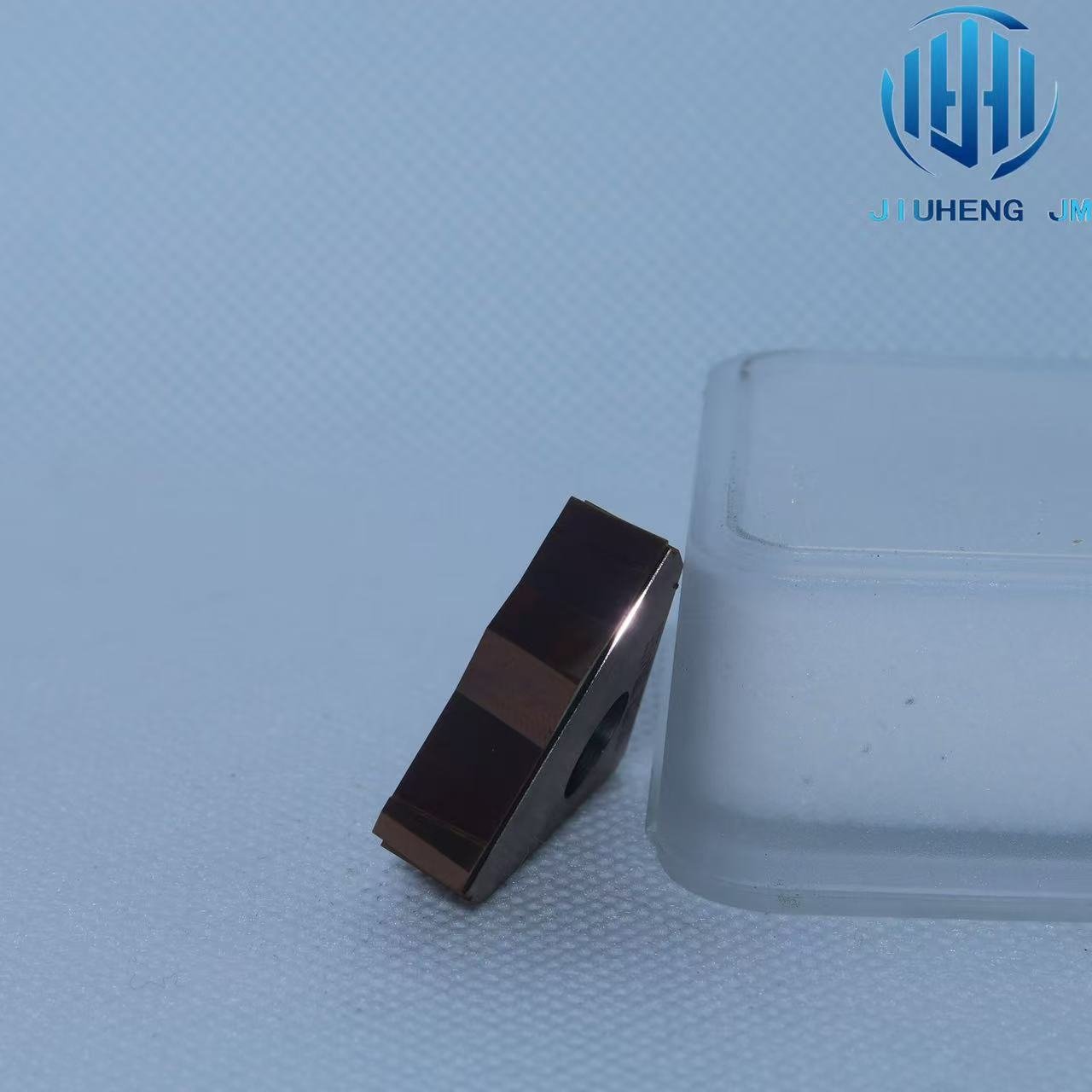

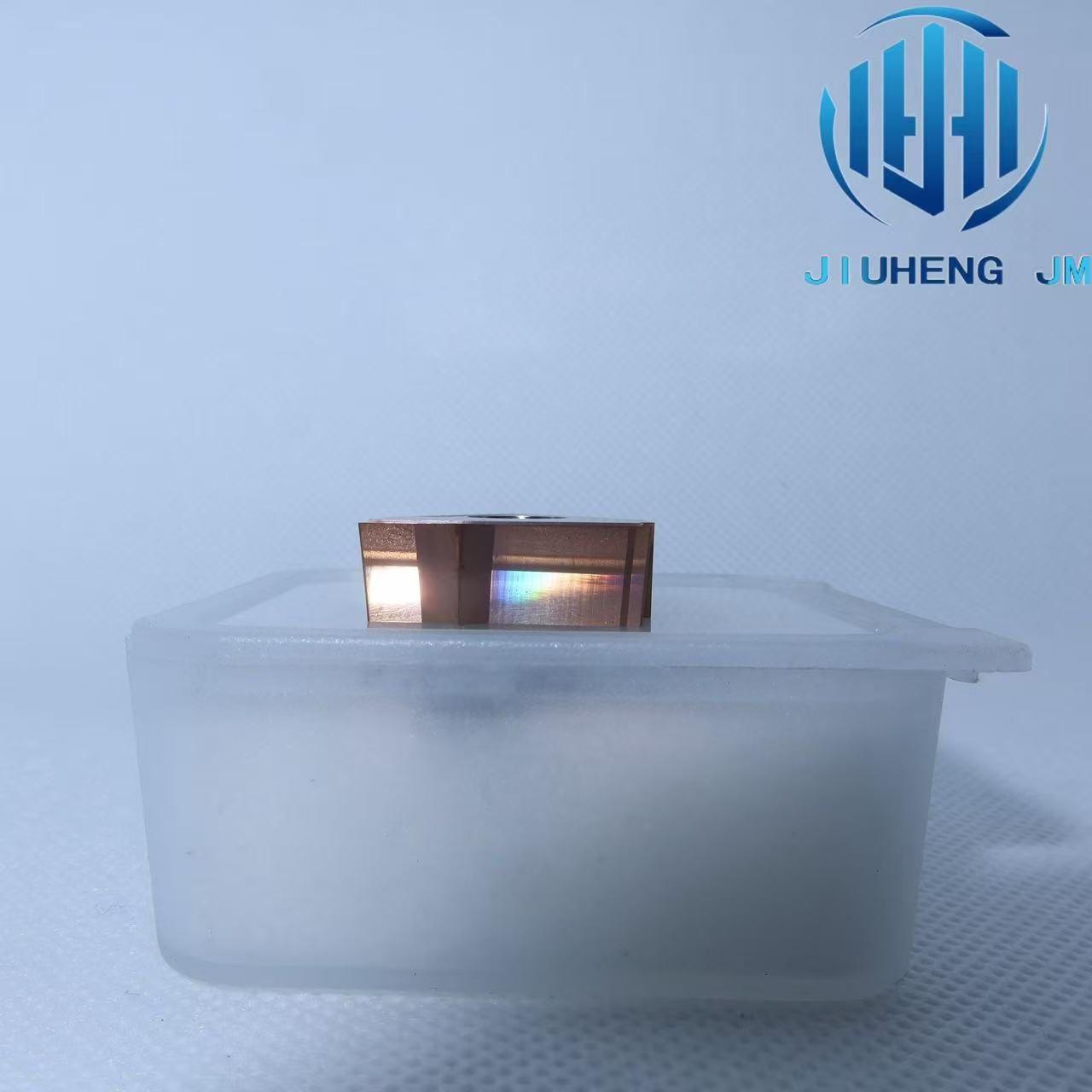

Cemented carbide: common base material, balancing wear resistance and toughness.

High-speed steel (HSS): suitable for low-speed machining with high-toughness requirements.

Coating technology: TiN, TiAlN and other coatings can improve heat resistance and wear resistance and extend tool life.

5. Efficient machining and applicability

Reduced processes: Single-pass machining forms complex contours directly, eliminating secondary operations.

Wide application: These tools effectively machine contours in various materials including steels, aluminum alloys, composites, and wood.

6. Precautions for use

The high rigidity requirements compel manufacturers to use vibration-damping machine tools and ultra-stable fixtures for successful profile machining.

Difficult to sharpen: non-standard tools require specialised equipment for sharpening, and maintenance costs are high.

Higher cost: customised tools are expensive, suitable for mass production or high value-added parts.

Typical Application Scenarios

Mould industry: Cavity processing of injection moulds and die-casting moulds.

Automotive: crankshafts, camshafts and other shaped parts.

Aerospace: impellers, wing surfaces, etc.