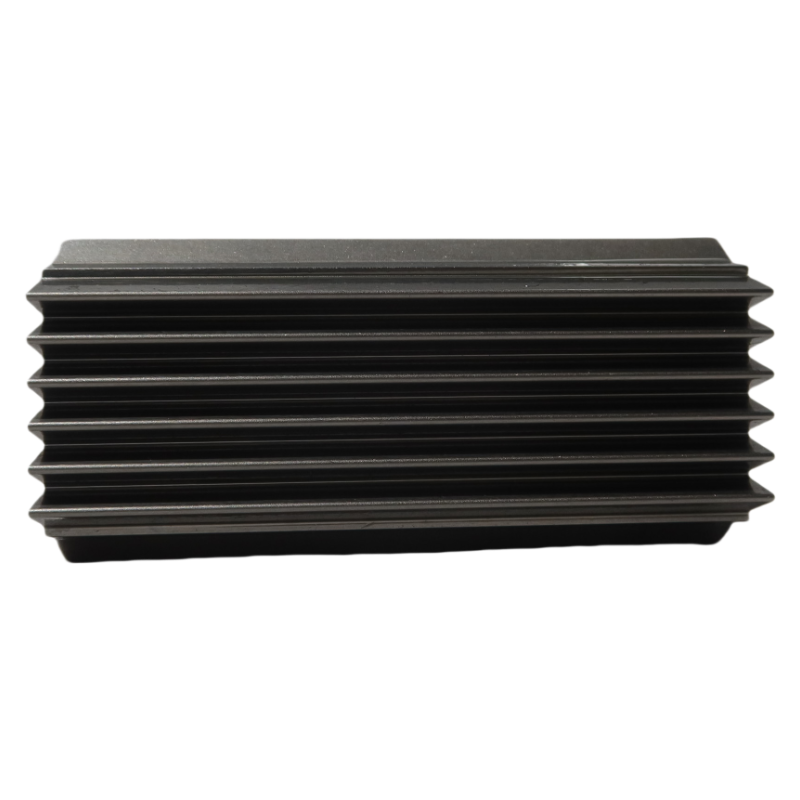

Forming Cutters are tools that are used to machine a specific contour, forming the surface of a workpiece by making one or more cuts with their pre-determined shape. Forming cutters with teeth refer to the type with a toothed cutting edge and are commonly used in milling and gear machining.

The core feature is the direct reproduction of the tool shape to the workpiece, which reduces the number of steps and is suitable for the efficient machining of complex contours.

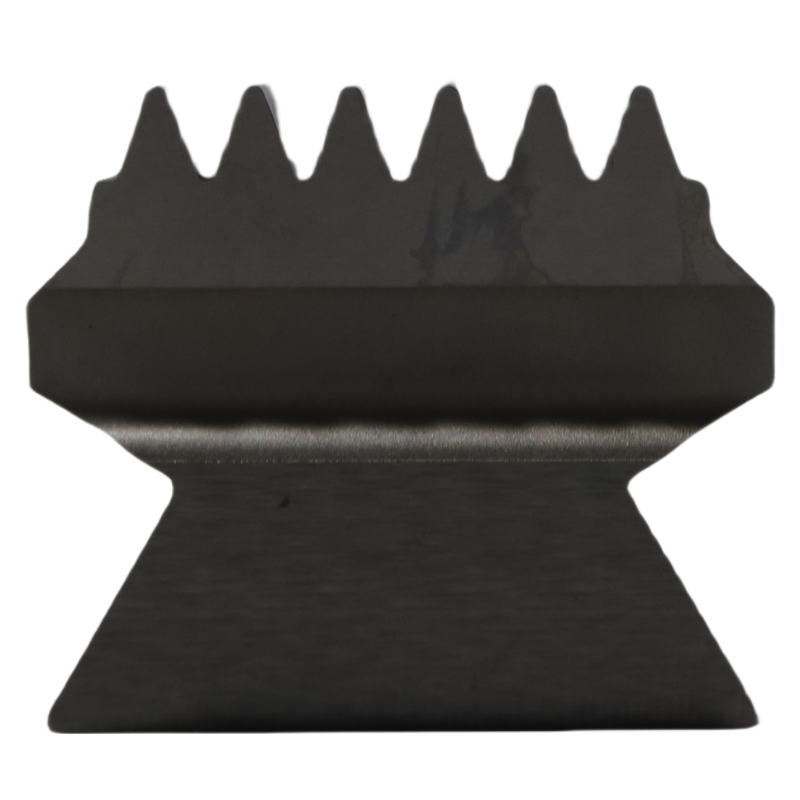

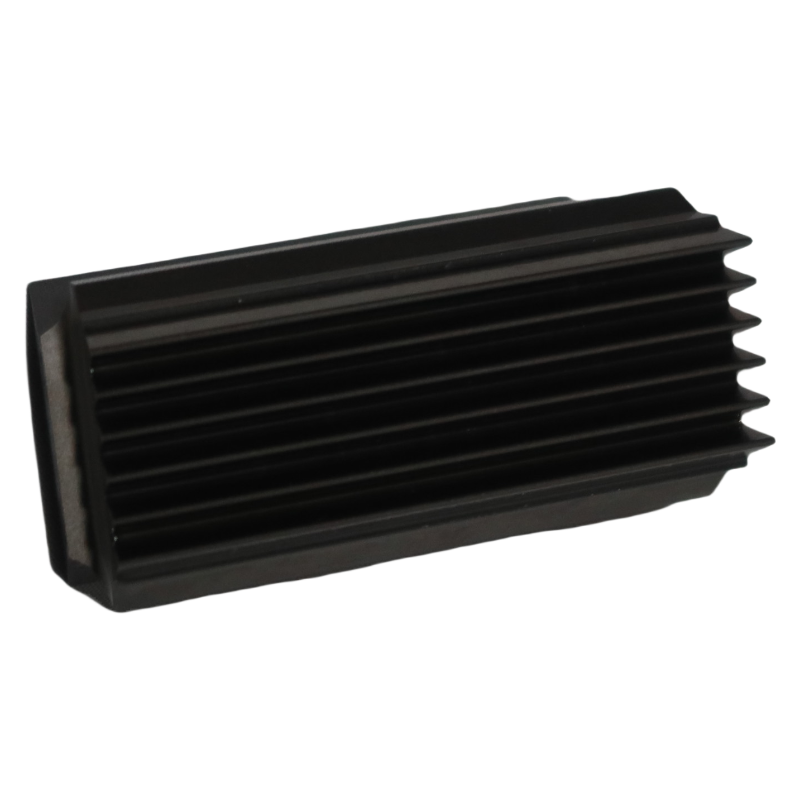

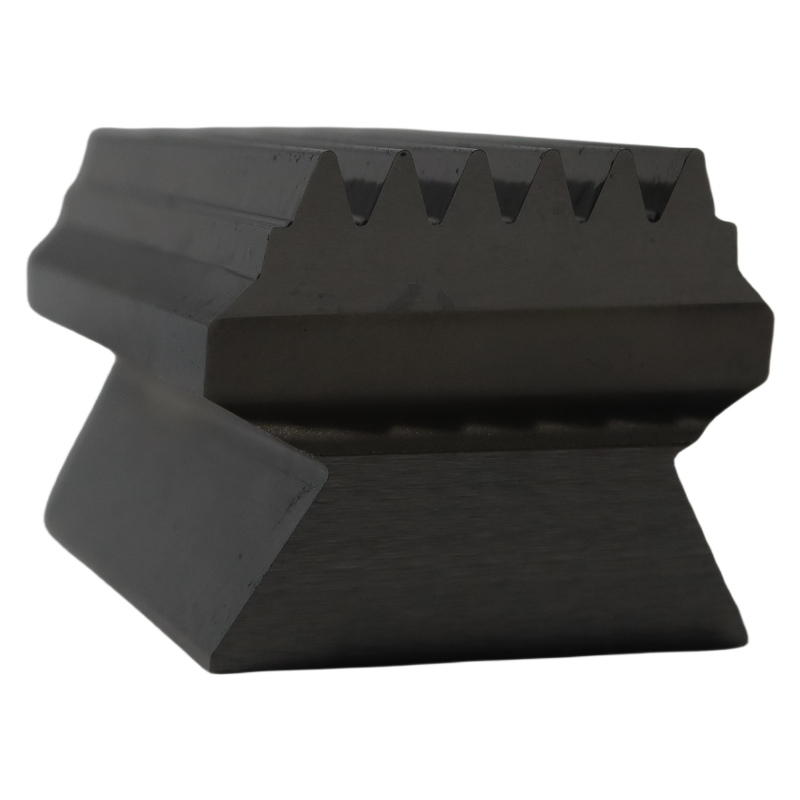

Structural features of toothed profile cutters

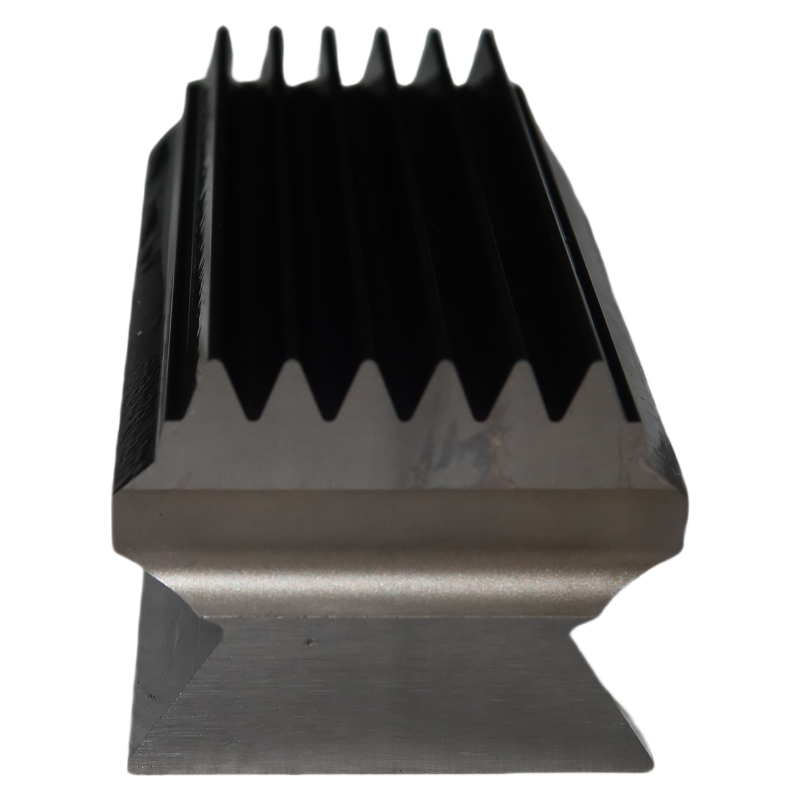

Tooth design:

Straight teeth: Suitable for simple contours, uniform cutting force.

Helical/bevelled teeth: reduces vibration, improves surface finish, suitable for deep groove machining.

Curved teeth: match complex surfaces (e.g. gear involute).

Materials: High-speed steel (HSS), carbide (high wear resistance), coated tools (TiN/TiAlN for longer life).

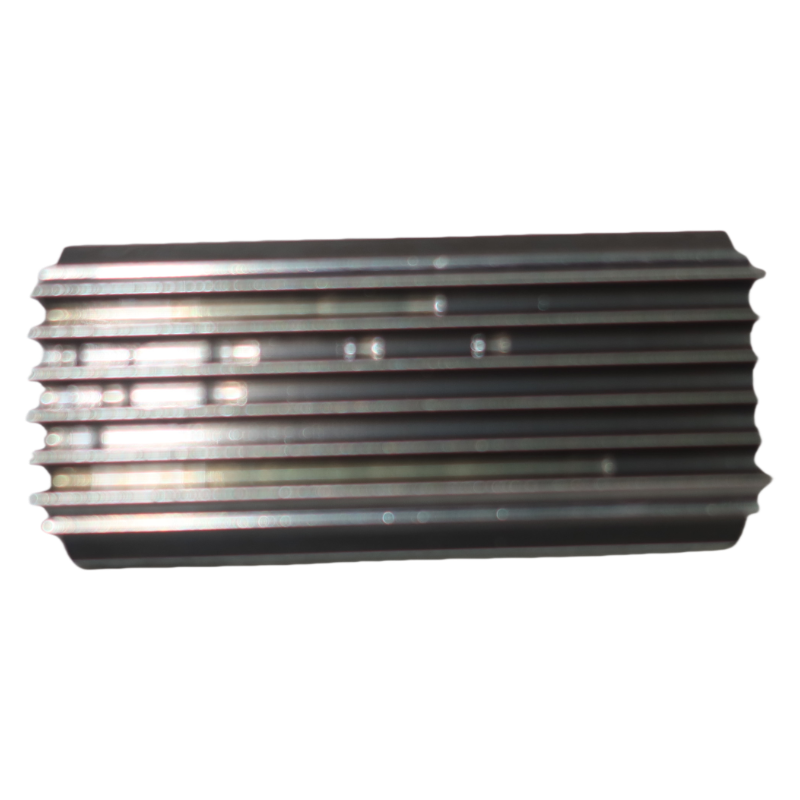

Number of teeth selection:

Many teeth: high precision, smooth surface, but little space for chip removal.

Few teeth: suitable for heavy cutting or soft materials, smooth chip removal.

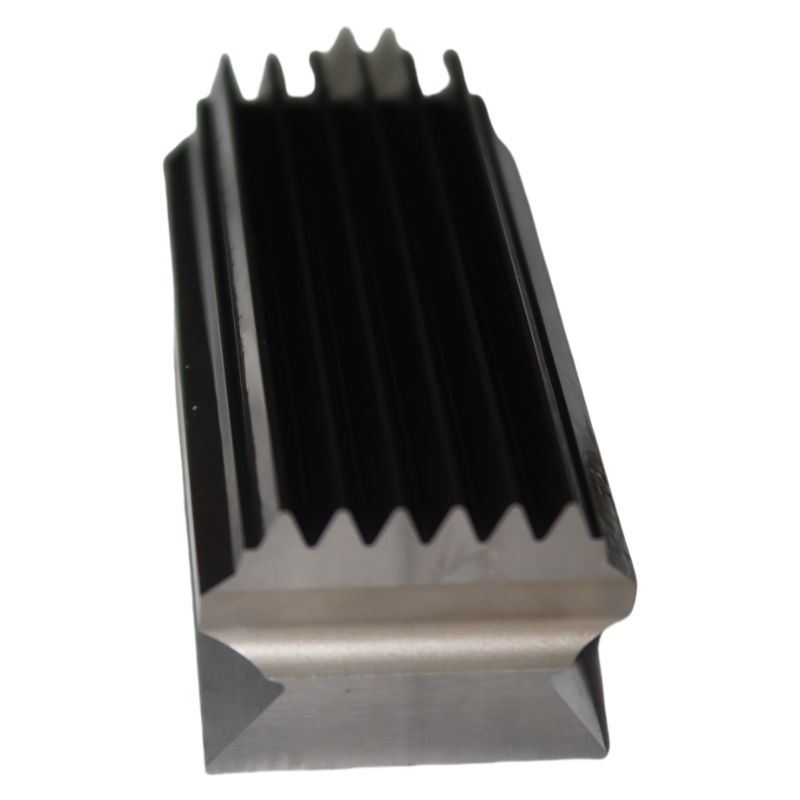

Application areas

Gear manufacturing: hobbing knife, gear shaping knife processing gear teeth.

Woodworking carving: Rapid prototyping of complex patterns and decorative lines.

Mould processing: cavity, relief and other surface processing.

Aerospace: turbine blade mortise and groove, special structural parts.