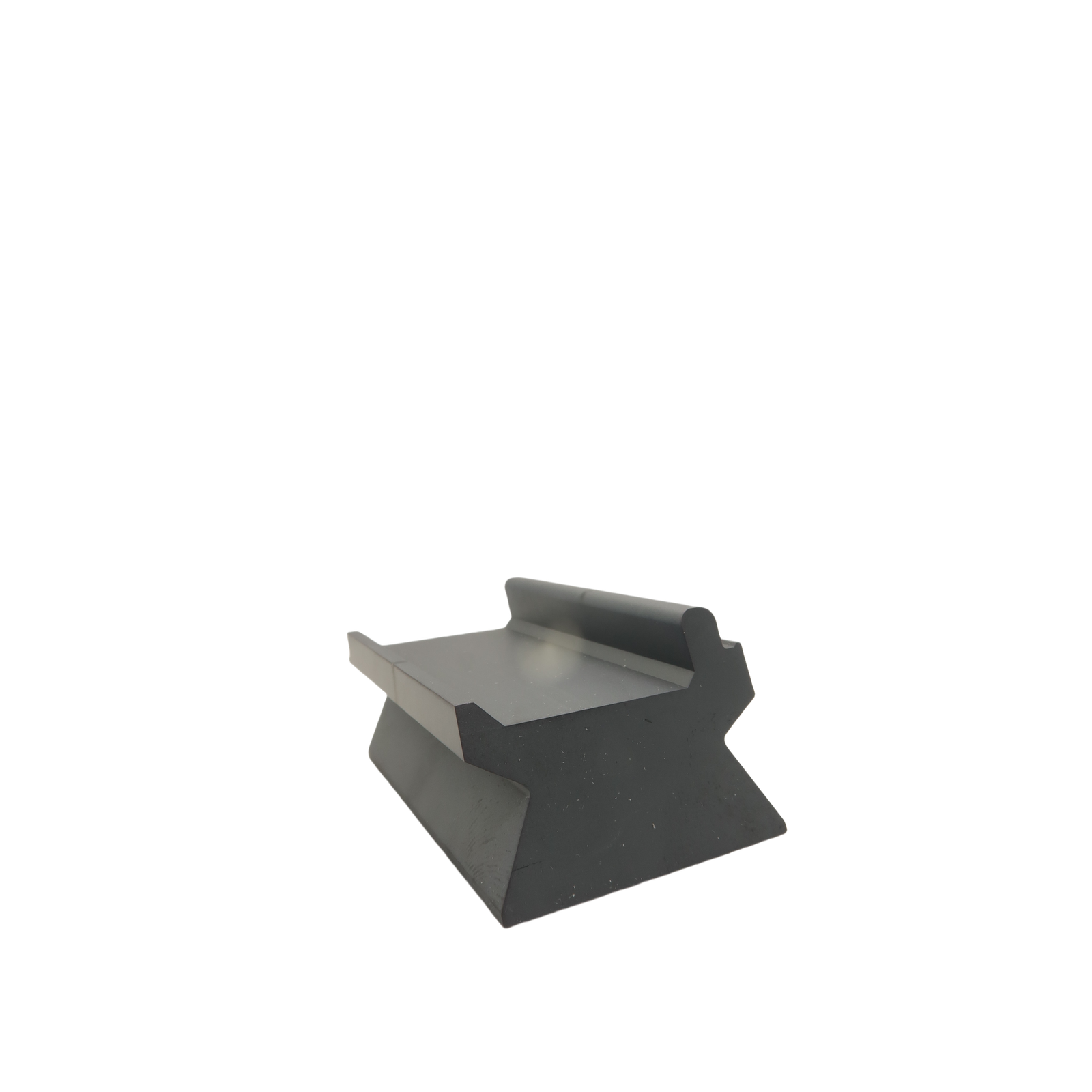

Forming Knife

Forming cutter is a customised tool designed for CNC machine tools. Its cutting edge shape is perfectly matched with the target contour of the workpiece. The cutter can directly form complex surfaces, gears, threads, and other structures in a single machining process, and it is suitable for high-efficiency and high-precision machining.

Core characteristics

Customised cutting edge shape: Designed according to workpiece requirements, such as gear tooth shape, turbine blade cavity, etc.

High-efficiency machining: complete complex contours in a single pass, reducing the need for multiple process switching.

High precision: CNC programming control, repeatability up to ±0.003mm.

Major Type

- Classification by structure:

Integral type: made of carbide or HSS, suitable for small and complex shapes (e.g. watch gear knives).

Welded: Carbide inserts are welded to the cutter body for economy and durability.

Indexable: Modular design with interchangeable blades (e.g. large turbine blade cutters).

Classification by use

Gear shaping cutter: Processing involute and cycloid tooth forms.

Contour forming cutters: for moulds, cams and other free-form surfaces.

Typical Application Scenarios

- Batch production: automotive gears, aerospace engine blades, hardware (e.g. door lock slots).

- Special materials: titanium alloy, high-temperature alloy profiling.

- High-precision fields: medical devices (e.g., curved surfaces of joint prostheses), moulds for optical components.