– High-precision, high-efficiency solutions for bearing manufacturing

I. Challenges of wheel bearing raceway machining

Wheel bearings are critical safety components in automobiles, and their raceway surface quality directly affects bearing life and vehicle NVH performance. Raceway machining faces two core challenges:

- High material hardness: Hardened steel (HRC 58-62) leads to intense tool wear;

- Precision requirements are stringent: raceway roundness error needs to be ≤5μm, surface roughness requires Ra ≤0.4μm. Conventional carbide tools are prone to dimensional drift due to rapid wear, and frequent tool changes increase production costs.

Second, the technological breakthrough of metal-ceramic bearing tool

The metal-ceramic bearing tool launched by Suzhou Jiuheng Precision Technology Co., Ltd. solves the pain point of the industry through the double innovation of material and structure:

1.Material Strengths

- Metal-ceramic (Cermet) matrix:iCN ceramic phase + Ni/Co metal bonded phase, hardness up to HRA 92-94, wear resistance up to 3 times higher than Cemented Carbide;

- Excellent red hardnesscutting performance is maintained at 1000°C, suitable for high-speed dry cutting ( V=80-100m/min);

- Low coefficient of friction: reduces cutting heat and avoids burns on the workpiece surface.

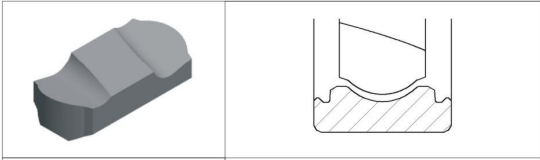

3. Specialised blade design

- Imitation blade: V-shaped blade, accurately matching the R angle of the raceway;

- Multi-axis capability: Supports 3-axis simultaneous machining, one-time forming of sealing groove/retaining edge/raceway.