Introduction: When ‘single-point breakthrough’ can not meet the needs of intelligent manufacturing

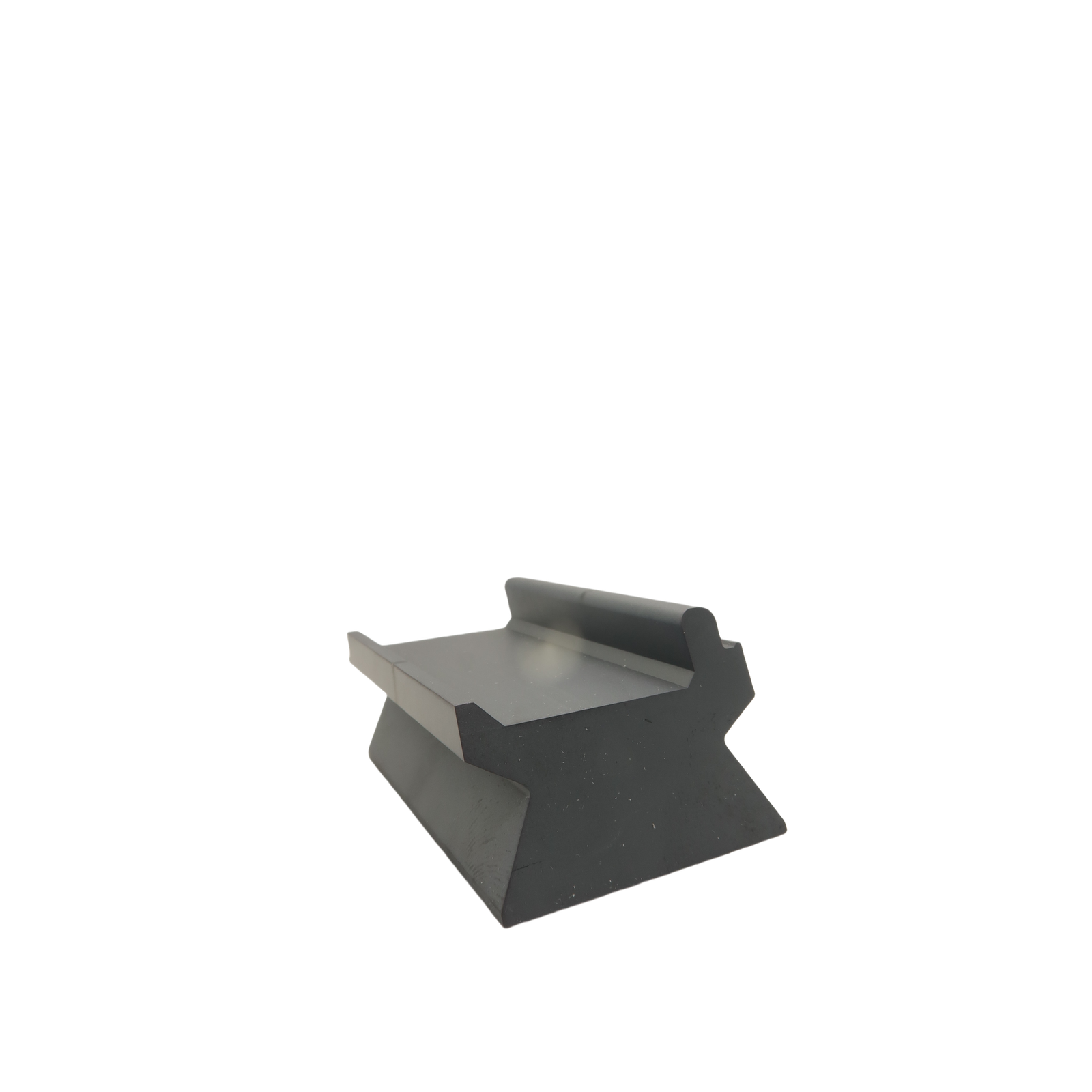

In the aero-engine blade curvature error ≤ 0.005mm, new energy vehicle motor shell processing beat compressed to 90 seconds today, the traditional single-edged tool has been complex to cope with the geometric complexity of the exponential growth of the processing challenges. Form Block Cutters is a revolutionary logic of ‘integral forming, once in place’, reconstructing the value chain of precision manufacturing!

I. The six descending advantages of forming block knives

- ‘Surgical precision control of complex contours

Molecular-level cutting edge fitting technology: the use of a five-axis grinding process so that the surface of the cutter body and the theoretical model of the workpiece deviation of ≤ 3μm (equivalent to 1/30 ofthe diameter of red blood cells)

Case study: A German turbine manufacturer optimised the surface roughness from Ra1.6μm to Ra0.4μm when machining guide vanes made of Inconel 718 alloy, achieving a mirror-polished finish.

- ‘Super time compressor’ for multi-process integration

Comparison of typical machining scenarios (automotive differential housing as an example):

| Process type | Conventional step-by-step machining | Forming block cutter programme |

|---|---|---|

| Number of tools | 7(roughing/finishing/chamfering, etc.) | 1 form block cutter |

| Number of tool changes | 6 times | 0 times |

| Total time | 43 mins | 18 mins |

- ‘Non-linear growth curve’ of tool life.

Stress field reconstruction technology: Optimisation of the internal lattice structure of the cutter body through finite element analysis, resulting in a 400% increase in chipping resistance.

Measured data: When machining titanium alloys, the life of the shaped block cutter is 2.8 times longer than that of a conventional ball end milling cutter (from 15 hours to 42 hours).

- The ‘invisible activator’ of machine performance.

Dynamic load balancing algorithm: the built-in chip monitors cutting force fluctuations in real time, and automatically adjusts the feed rate to keep the power stable at ±2%.

Benefit: After the use of a Russian machine tool factory, the spindle bearing replacement cycle has been extended from 6 months to 16 months.

- ‘Geometric free dimension’ for personalisation and customisation

Parametric design cloud platform: supports online import of STEP/IGES files, generating customised toolpath solutions within 24 hours.

Industry breakthrough: Successfully realised negative angle reverse cutting of helicopter rotor blade tongue and groove (not possible with traditional tools).

- ‘Carbon Footprint Reduction Expert’ for Green Manufacturing

Life Cycle Analysis (LCA): 52% reduction from raw materials to end-of-life recycling.

Key indicators:

68% reduction in coolant consumption (due to improved chip removal efficiency)

41% reduction in power consumption (reduced machining time)

II Value Quantification Model for Purchasing Decision Makers

Return on Investment (ROI) Calculation Formula:

ROI=Pt(Ts×Rh+Ct×Nt)−Pt×100%

- TsTs= Time saved per piece (hours)

- RhRh = Hourly machine tool rate (€/h)

- CtCt = Conventional tool cost per unit (€)

- NtNt = number of conventional tools replaced

- PtPt = Purchase price of forming block cutter (€)

Typical case:

An Italian brake disc manufacturer purchased €2450 formed block cutters to replace 6 conventional cutters (unit price €420), with an annual ROI of 317%.

Conclusion: It’s not a tool upgrade; it’s an evolution in manufacturing philosophy!

When machining efficiency begins to compete in seconds, the forming block tool is redefining the nature of ‘metal cutting’ – from discrete tool movement to the overall shape of the material reconstruction. Choosing it is not only choosing a tool but also choosing a passport to enter the core circle of intelligent manufacturing.