Fields of Application

Aerospace Industry

Aircraft structural component machining: milling of aluminium alloys, titanium alloys and other materials to ensure lightness and strength of structural components.

Engine blade machining: complex curved surfaces are machined to ensure the aerodynamic performance of the blades.

Landing gear machining: grooving and notching of high-strength steels to ensure the durability and safety of landing gear.

Technical Advantage

-

High precision: meet the ultra-high precision requirements for parts in the aerospace industry

-

Customisation: Provide tools with special coatings and geometries according to customer requirements.

- Efficiency: reduce machining time and increase productivity.

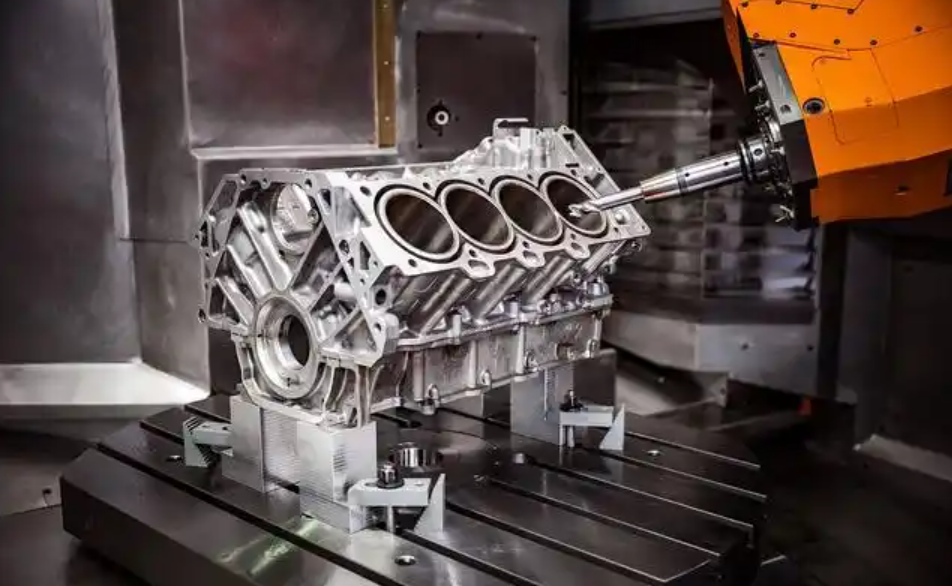

Automotive Manufacturing

Engine block machining

High-precision milling of block surfaces ensures sealing and durability.

High efficiency

One-piece grooved inserts reduce tool change time and increase productivity.

Transmission machining

Grooving and notching are used to improve the precision and transmission efficiency of transmission gears.

High Precision

Ensure component dimensional tolerances are within the micron level.

Wheel hub machining

Complex surface machining to ensure the lightweight and strength of the wheel hub.

Durability

High-quality carbide materials are used to extend tool life.

Mould Manufacturing

Mould cavity machining: High-precision milling of complex surfaces to ensure the surface finish of the mould.

Mould core machining: slotting and grooving to ensure the mould’s assembly precision is met.

High-hardness material machining: for hardened steel, carbide and other materials.

Technical Advantage

-

High efficiency: Reduce machining time and improve the efficiency of mould manufacturing.

-

Durability: Adopt special coating technology to extend tool life.

-

Flexibility: Support multiple machining strategies to adapt to different mould design requirements.

General Machinery

Metal parts machining

It is suitable for milling, grooving, grooving and other machining of steel, cast iron, aluminium alloy and other materials.

Versatility

Suitable for a wide range of materials and processing needs.

Complex shape machining

CNC tools are used for machining parts with complex geometries.

High efficiency

reduce processing time and improve productivity..

Customisation

support customer customisation, provide funny machining solutions according to customer needs

Durability

High-quality carbide materials are used to extend tool life.